Recent achievements of the team - Statistics and Analysis of Lath Martensite Transformation based on in-situ observation and video processing

Our team published the paper “Statistics and Analysis of Lath Martensite Transformation based on in-situ observation and video processing”. The School of Computer Engineering and Science, Shanghai University was the first department.

Research methods in materials science are undergoing a new transformation with the development of artificial intelligence and scientific equipment. The shift from the traditional way of studying material properties based on static images to revealing the process of material microstructural changes through dynamic videos has not only enhanced the depth of research, but also dramatically improved the efficiency of data processing. Especially in the field of steel manufacturing, the study of the phase transition from austenite to martensite is crucial for optimizing material properties.

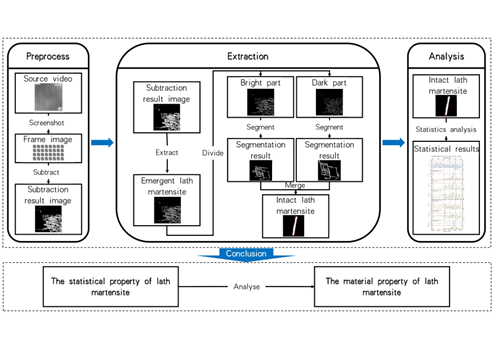

In this paper, we propose a dynamic video-based method for analyzing the phase transformation of slat martensite, which breaks through the limitations of static image research. The method can efficiently segment and extract the image data of individual slat martensite, and analyze its changing law in dynamic video. By counting several key attributes including the number, size, area and direction of the transformed slats, we realize a comprehensive analysis of the dynamic characteristics of martensite phase transformation. This method not only improves the information extraction efficiency, but also provides important data support for revealing the martensite phase transformation mechanism and optimizing the steel manufacturing process.

The results show that dynamic video studies can significantly improve the efficiency and accuracy of data processing, especially when facing the complex morphology and rapid transformation process of slat martensite. In the future, I would like to apply this method to the study of more material systems to further promote the optimization of material properties and process improvement.