Team Recent Achievement - Zhang Hongkun's Publication in a High-Impact Journal

Our team, in collaboration with Professor Wu Jinbo’s research group from the Institute of Materials Genomics Engineering, has recently published a paper titled “Unclonable Micro-Texture with Clonable Micro-Shape towards Rapid, Convenient, and Low-Cost Fluorescent Anti-Counterfeiting Labels” in the international journal “Small” (IF: 11.459, top in Zone 1 according to JCR and Chinese Academy of Sciences SCI journal rankings). “Small” is one of the most influential top-tier academic journals in the field of engineering, technology, and materials science. In this publication, Shanghai University is listed as the primary affiliation, with Zhang Hongkun, a master’s student from the School of Computer Engineering and Science, and Lin Yuhong and Feng Jingyun, both master’s students from the Institute of Materials Genomics Engineering, being the co-first authors. Professor Wu Jinbo from the Institute of Materials Genomics Engineering and Associate Professor Han Yuexing from the School of Computer Engineering and Science are the corresponding co-authors. This work has received strong support from Academician Zhang Junyi, Professor Wen Weijia, and Professor Qi Yabing from the Okinawa Institute of Science and Technology Graduate University (OIST) in Japan.

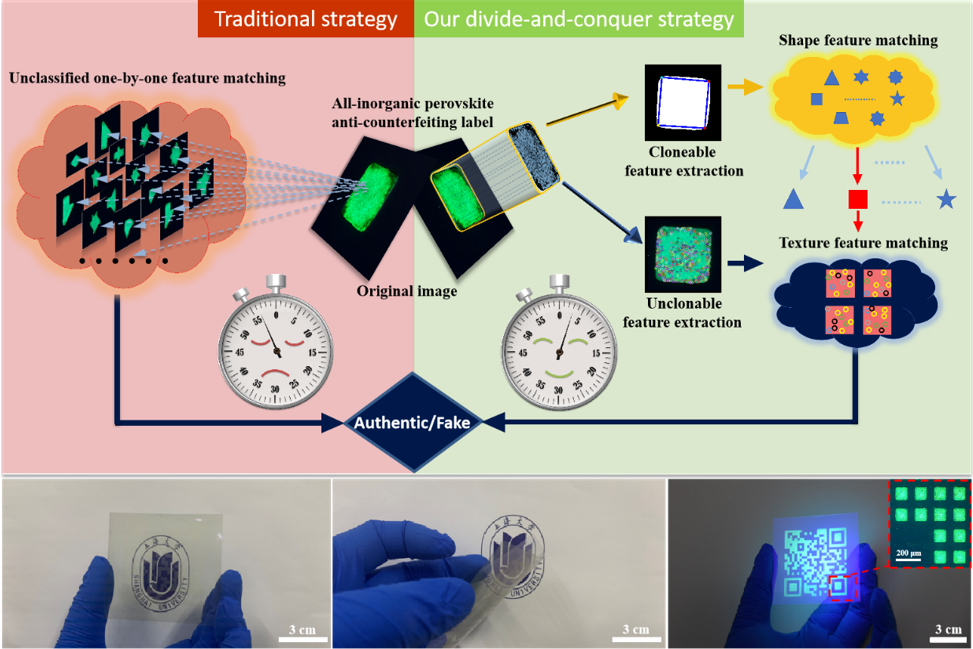

Counterfeit products, ranging from high-end luxury goods to medical supplies, not only cause significant economic losses but also pose a significant threat to people’s health. The currently widely used anti-counterfeiting labels are based on deterministic production processes, which are simple to replicate for counterfeiters. Developing anti-counterfeiting labels with physical unclonable functions (PUFs) is a feasible solution. However, traditional PUF recognition techniques require matching against all images in a database, resulting in high production costs and slow identification speed.

To address the aforementioned issues, the research team utilized high-throughput parallel non-continuous dewetting technology to fabricate a multifunctional label with four layers of anti-counterfeiting capabilities. The first layer of anti-counterfeiting is achieved through the fluorescence of perovskite crystal films. These films exhibit unique fluorescence properties that can be used for authentication. The second layer of anti-counterfeiting involves macroscopic patterns composed of basic units, such as QR codes, which can carry information and serve as additional security features. The third layer of anti-counterfeiting is based on microscale basic units with diverse shapes. These units provide an additional level of security as their distinct shapes can be difficult to replicate. The fourth layer of anti-counterfeiting is achieved through the use of non-reproducible textures formed through self-assembly processes. These random textures create a unique and unclonable pattern, further enhancing the security of the label. By combining these four layers of anti-counterfeiting features, the research team has developed a label that offers enhanced security and counterfeit prevention across multiple levels.

Our main work involved designing and establishing a database that stores authentic thin film patterns, which includes shape and texture databases. For shape recognition, we employed the CNL (Control the Number of Landmarks) method, an improved Hough Transform method, and shape space theory. These techniques were utilized to accurately identify the shapes present in the labels. Subsequently, we utilized the GMS (Grid-based Motion Statistics) method to further recognize the textures of the labels. This method leverages grid-based analysis and motion statistics to effectively identify and differentiate the unique textures embedded in the labels. By combining the shape recognition techniques and texture identification using GMS, our research team has developed a comprehensive approach for the recognition and authentication of the labels based on their shape and texture characteristics.

In practical applications, anti-counterfeiting micro-patterns are captured using smartphones or portable microscopes and then fed into recognition software for matching and identification. The various contour shapes of the nanocrystal films are refined and classified, serving as “classification symbols” for image data recognition. By employing this “divide and conquer” strategy in the recognition process, the verification time can be reduced by more than 20 times. Combining high-throughput materials fabrication techniques with data-driven material applications, our approach achieves low reagent costs (2.1 × 10−4 USD), simple and fast authentication (total time of 12.17 seconds), and high coding capacity (2.1 × 10623). This integration of advanced technologies enables cost-effective and efficient anti-counterfeiting measures, providing a robust solution with high coding capacity and fast authentication for a wide range of applications.

The related work has received funding from various sources, including: 1. National Key Research and Development Program (2020YFB0704503, 2018YFB0704400, 2018YFB0704402): These programs are part of the national strategic research initiative that supports key research and development projects in China. 2. National Natural Science Foundation of China (21775101): This foundation provides funding for basic and applied research in various scientific disciplines. 3. 111 Project (D16002): The 111 Project is a national recruitment program that aims to attract and retain top-tier talent for research and innovation in Chinese universities. 4. Shanghai Municipal Science and Technology Commission Project (20ZR1419000): This project is funded by the Shanghai municipal government to support research and development activities in the city. The support from these funding sources has played a crucial role in facilitating the progress and success of the research work in developing innovative anti-counterfeiting technologies and materials.

Essay: https://onlinelibrary.wiley.com/doi/10.1002/smll.202100244